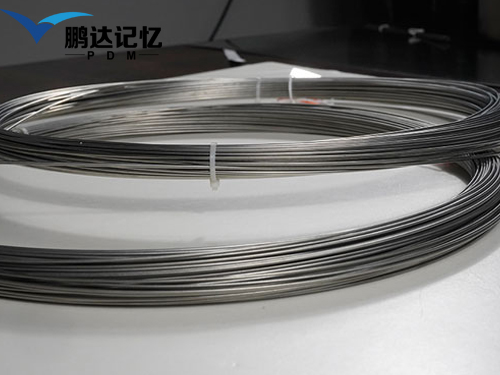

In 1932, Swedish Holland observed the "memory" effect for the first time in the gold cadmium alloy, that is, once the shape of the alloy is changed, once heated to a certain jump temperature, it can magically change back to the original shape. People call the alloy with this special function as shape memory alloy. The development of memory alloy is only more than 20 years, but because of its special effect application in various fields, it is widely attracted the attention of the world, known as "magical functional materials". In 1963, bill of the Naval Ordnance Research Institute of the United States found that in a certain temperature range higher than the room temperature, a nickel titanium alloy wire was burned into a spring, and then it was straightened in cold water or cast into square, triangle and other shapes, and then placed in hot water above 40 ℃, the alloy wire returned to the original spring shape. Later, it was found that some other alloys have similar functions. This kind of alloy is called shape memory alloy. Every shape memory alloy which is made up of certain elements according to a certain weight ratio has a transformation temperature. Above this temperature, the alloy is processed into a certain shape, then cooled to below the transformation temperature, artificially changed its shape, and then heated to above the transformation temperature, and the alloy will automatically return to the original shape processed above the transformation temperature

As early as in the Qin Dynasty, there were memory metals, such as Gou Jian, the king of Yue and the sword of Qin.

In 1932, Swedish Holland observed the "memory" effect for the first time in the gold cadmium alloy, that is, once the shape of the alloy is changed, once it is heated to a certain jump temperature, it can magically change back to the original shape. People call the alloy with this special function as shape memory alloy. The development of memory alloy has not been more than 20 years, but because of its special effect application in various fields, it is widely attracting the attention of the world and known as "magical functional material".

In 1963, bill of the Naval Ordnance Research Institute of the United States found that in a certain temperature range higher than the room temperature, a nickel titanium alloy wire was burned into a spring, and then it was straightened in cold water or cast into square, triangle and other shapes, and then placed in hot water above 40 ℃, the alloy wire returned to the original spring shape. Later, it was found that some other alloys have similar functions. This kind of alloy is called shape memory alloy. Every shape memory alloy which is made up of certain elements according to a certain weight ratio has a transition temperature. Above this temperature, the alloy will be processed into a certain shape, then cooled to below the transition temperature, artificially changed its shape, then heated to above the transition temperature, and the alloy will automatically return to the original shape processed above the transition temperature.

In 1969, the "shape memory effect" of nickel titanium alloy was first applied in industry. A unique pipe joint device has been adopted. In order to connect the two metal pipes to be butted, a shape memory alloy with the transition temperature lower than the service temperature is selected. When the transition temperature is higher, a short pipe with the inner diameter slightly smaller than the outer diameter of the pipe to be butted is made (used as the joint). Then the inner diameter is slightly expanded under the transition temperature, and the connected pipe is put at the transition temperature of the joint The joint will automatically shrink and fasten the connected pipe to form a firm and tight connection. In the United States, a nickel titanium alloy joint is used in the oil pressure system of a fighter jet, and there has never been oil leakage, falling off or damage.

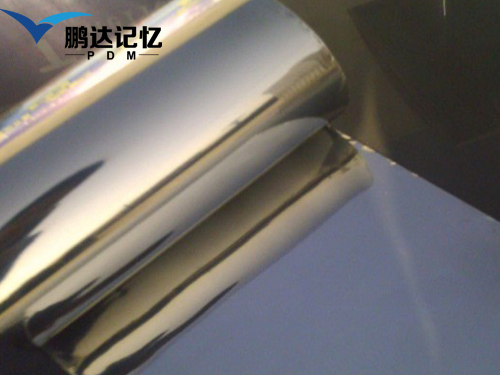

On July 20, 1969, American astronauts left their footprints on the moon for the first time in the Apollo 11 lunar module, and transmitted information between the moon and the earth through a hemispherical antenna with a diameter of several meters. How was this giant antenna brought to the moon? It was made of a shape memory alloy material, which was first made at a temperature above its transition temperature according to the predetermined requirements, then compressed into a mass by lowering the temperature, and then loaded into the lunar module to take it to the sky. After being placed on the moon, the antenna "remembers" its original appearance and becomes a huge hemisphere when it reaches the transition temperature of the alloy in the sunlight.

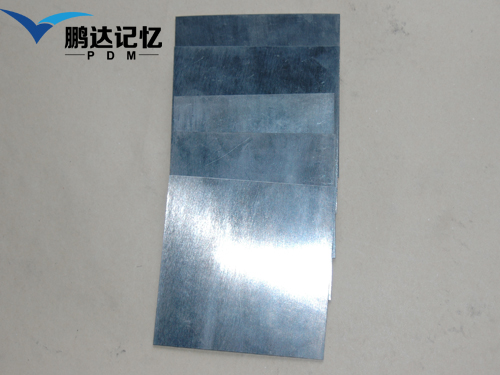

Scientists added other elements to the nickel titanium alloy to further research and develop new nickel titanium shape memory alloys, such as qinni copper, titanium nickel iron, titanium nickel chromium, etc.; in addition, there are other kinds of shape memory alloys, such as: copper nickel alloy, copper aluminum alloy, copper zinc alloy, iron alloy (Fe Mn Si, Fe PD), etc.

Shape memory alloys have wide application prospects in bioengineering, medicine, energy and automation.

current location:

current location: