The 20th century is the era of mechatronics. Sensor integrated circuit drive is the most typical mechanical and electronic control system, but it is complex and huge. Shape memory material has dual functions of sensing and driving, which can realize miniaturization and intelligence of control system, such as holographic robot, millimeter level super micro manipulator, etc. The 21st century will be the era of material electronics. The action of SMA robot is not affected by any environmental conditions except temperature, and it is expected to play an important role in high-tech fields such as reactor, accelerator, space laboratory and so on.

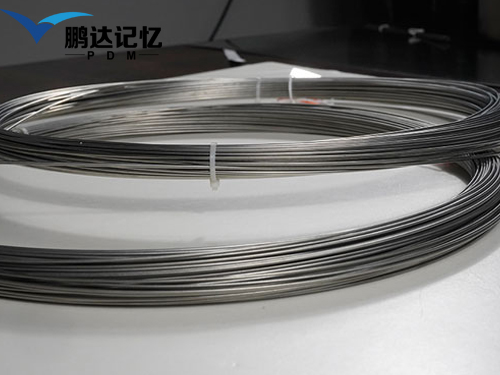

When it comes to alloys, of course, memory alloys are the most interesting alloys. Metal has memory, which is an accidental discovery: in the early 1960s, a research team of the U.S. Navy brought some nitinol alloy wires from the warehouse for experiments. They found that these alloy wires were crooked and inconvenient to use, so they straightened them one by one. During the experiment, strange phenomena happened. They found that when the temperature rose to a certain value, the straightened Ni Ti alloy wires suddenly returned to the original bending state. They were good at observation and did many experiments repeatedly. The results confirmed that these filaments do have "memory".

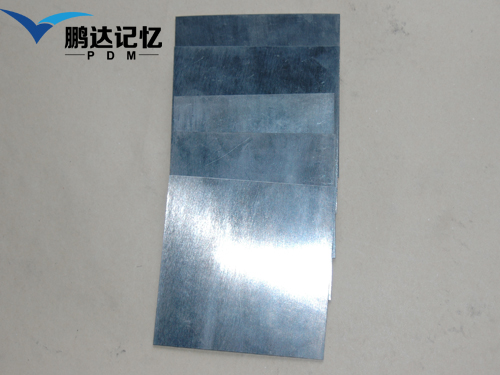

The discovery of the US Naval Research Institute has aroused great interest in the scientific community, and a large number of scientists have conducted in-depth research on it. It is found that Cu Zn alloy, Cu al Ni alloy, Cu Mo Ni alloy, Cu Au Zn alloy all have this unique ability. In a certain range, people can change the shapes of these alloys according to their needs. At a certain temperature, they will automatically return to their original shapes, and the "change restore" can be repeated many times. No matter how they change, they can always remember their shapes at that time. At this temperature, they will reproduce the original shapes exactly. People call this phenomenon shape memory effect, and metal with this shape memory effect is called shape memory alloy for short.

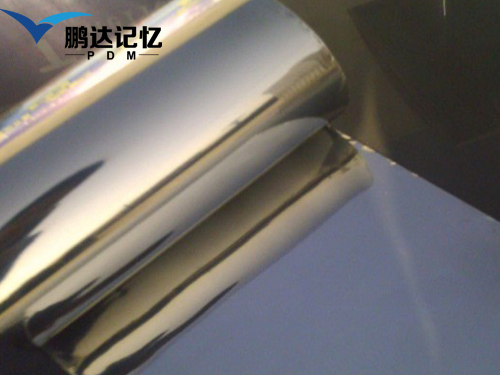

Why do these alloys have this shape memory effect? How do they remember their original form? It is difficult to explain the memory effect of the alloy with the general metal bond theory and free electron theory. Under certain temperature conditions, the memory alloy can return to its original shape, which provides an excellent example for the movement of the electrons outside the core - the movement with the change of temperature. It is precisely because the formation of the alloy is the mutual melting of the liquid metal under the high temperature condition. Because the structural elements of the liquid metal are different, the structural elements of this element and the structural elements of another metal are evenly distributed. After solidification, the microstructure is an orderly arrangement of different kinds of structural elements in proportion, and the electromagnetic force is the main cohesion of the alloy object.

Electromagnetic force is formed by the operation of valence and electron, and the operation rate of electron changes with the temperature condition. Therefore, the electromagnetic force (size, direction, acting point) in the object also changes with the temperature condition. Thus, the internal force of metal objects changes with the temperature conditions, but these changes are not obvious in the range of small temperature difference, only when the temperature changes greatly (several hundred degrees Celsius). Generally, metal can produce plastic deformation after being stressed. For example, a wire is bent. At the bending position, the electromagnetic force is interfered by external force, resulting in minor adjustment of the price of electromagnetic force and the operation plane of electron, and one plastic deformation is completed.

Because different kinds of structural elements are mixed and distributed with each other, although the size of the structural elements and the electromagnetic force are different, they speed up their own valence and operation, and the adjacent phases are safe under certain temperature conditions. After the external force, the electromagnetic force is interfered by the external force, and the operation plane of valence and electron is adjusted at a small angle, and the object produces plastic deformation. In this plastic deformation, the operation of some adjusted valence and electron is not stretching. When the temperature condition changes, the rate of valence and electron will change accordingly. When the temperature returns to the condition of phase comfortable stretching (transition temperature), the operation of non stretching valence and electron will immediately return to the current rate, and the electromagnetic force will change accordingly, so that the price and operation of adjacent structural elements will also be adjusted accordingly, all of them will return to the original stretching state, so the whole object will also return It's back to its original state. This is the memory process of memory alloy.

In fact, the memory of metal has been found for a long time: when a straight wire is bent into a right angle (90 °), once it is loosened, it will return a little bit, forming an angle greater than 90 °. To straighten a bent wire, you must fold it to more than 180 ° and then loosen it, so that it can just return to a straight line state, which is the Chinese idiom for overcorrection. And the alloy with better memory is the spring (steel spring here, steel is FERROCARBON alloy). The spring firmly remembers its shape. When the external force is removed, it immediately returns to its original appearance. However, the memory temperature of the spring is very wide, unlike memory alloy, which has a specific transition temperature, so it has some special functions.

current location:

current location: