Memory alloy, because it has more than one million times of recovery ability, many people call it "living alloy" precisely because memory alloy is a kind of "living alloy", using its shape change under a certain temperature, we can design various automatic control devices, its use is expanding.

Mechanical use

Memory alloy is widely used. For example, mechanical fastening pin, pipe joint, fire alarm on electronic equipment, plug-in parts, soldering of integrated circuit, artificial heart valve, spine straightening rod, skull repair and reshaping, oral tooth correction and jaw repair operation. It will also play a magic role in communication satellites, color TV sets, temperature controllers and toys. It will also become a new type of material memory alloy in modern navigation, aviation, aerospace, transportation, light textile and other fronts, which has been used in pipeline combination and automatic control. The sleeve made of memory alloy can replace welding. The method is to complete the tube end at low temperature After heating, the sleeve shrinks back to its original shape, forming a tight joint. The hydraulic system of the U.S. Navy aircraft uses 100000 such joints, which have not been leaking or damaged for many years. It is very convenient to repair the damaged ships and submarine oil pipelines with memory alloy fittings. In some parts with inconvenient construction, the pin is made of memory alloy, which is installed into the hole for heating, and its tail end is automatically separated and curled to form a single-sided assembly.

Memory alloy is especially suitable for thermal machinery and constant temperature automatic control. It has been made into room temperature automatic opening and closing arm, which can open the ventilation window in the daytime when the sun shines, and automatically close when the room temperature drops at night. There are many design schemes of memory alloy heat engine, which can work between two kinds of medium with low temperature difference, thus opening up a new way to utilize industrial cooling water, nuclear reactor waste heat, ocean temperature difference and solar energy. At present, the common problem is that the efficiency is not high, only 4% - 6%, which needs further improvement.

Medical use

The application of memory alloy in medical treatment is also very attractive. For example, the bone plate used for bone grafting can not only fix the two broken bones, but also produce compression force in the process of restoring the original shape, forcing the broken bones to join together. Tooth straightening wire for dentistry, long clip for ligation of cerebral aneurysm and vas deferens, and support plate for spine straightening are all started by body temperature after being implanted into human body. Thrombus filter is also a new product of memory alloy. After the stretched filter is implanted into the vein, it will gradually return to the network, thus preventing 95% of the clots from flowing to the heart and lungs.

The artificial heart is a kind of organ with more complex structure. The muscle fiber made of memory alloy and the ventricle of elastomer film can imitate the contraction of the ventricle. Now pumping water has been successful.

Because memory alloy is a kind of "living alloy", we can design a variety of automatic control devices by using its shape change under a certain temperature, and its application is expanding.

Early application

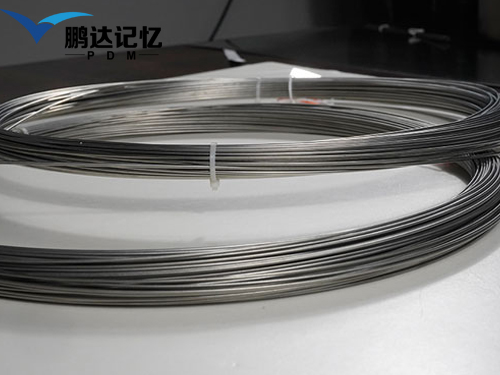

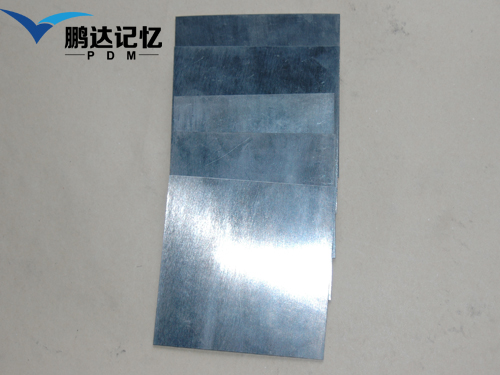

Shape memory alloy is used in pipe joints and fasteners. The inner diameter of the casing is 4% smaller than the outer diameter of the pipe to be connected by using shape memory alloy, and then the casing is expanded by about 8% at liquid nitrogen temperature. During assembly, the casing is taken out from liquid nitrogen and the pipe to be connected is inserted from both ends. When the temperature rises to normal temperature, the sleeve shrinks to form a tight seal. This kind of connection can prevent leakage, which is much better than welding. It is especially suitable for dangerous occasions such as aviation, aerospace, nuclear industry and submarine oil pipeline.

Space technology application

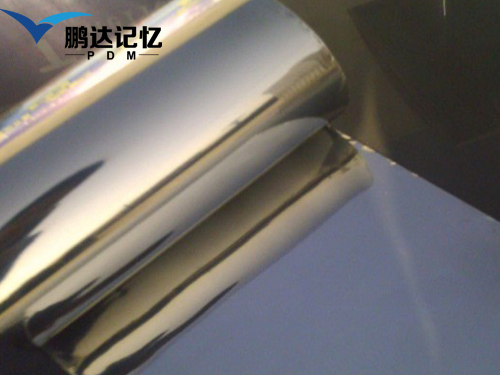

The encouraging application of memory alloy is in aerospace technology. On July 20, 1969, Apollo 11 lunar module landed on the moon, realizing the dream of the first trip to the moon. After the astronauts landed on the moon, a hemispherical antenna several meters in diameter was placed on the moon to send and receive information to the earth. A few meters antenna was installed in a small lunar module and sent to space. The antenna is made of memory alloy which was just invented at that time. The very thin memory alloy material is first made according to the predetermined requirements under normal conditions, and then it is pressed into a ball by reducing the temperature, and then it is loaded into the lunar module and taken to the sky. After being placed on the moon, the temperature rises in the sunlight. When the transition temperature is reached, the antenna "remembers" its original appearance and becomes a huge hemispherical shape.

current location:

current location: